Front Loading Tapered Interlocks - Mould & Die Solutions

Main menu:

- About Us

- Partners

-

Products

- HOT RUNNER SOLUTIONS

-

MOULD COMPONENTS

- Alignment

- Cooling

- Ejection

- General Mould Components

- Fastening

-

PRE-ENGINEERED COMPONENTS

- Ejection Control

- Limit Switches

- Machine Nozzles and Filters

- Mould Performance Monitoring

- Moulding Threads and Undercuts

- Parting Line Sequence Control

- Rapid Mould Changes

- Stack Mould Systems

- HYDRAULIC CYLINDERS

- MOULD BASES

- MOULD POLISHING

- Delivery

- Technical Info

- Terms & Conditions of Sale

- Contact Us

- E-Multi - Maximise the capabilities of you existing IM machines

- Latest developments - CVe Mould Monitoring

- NEW! Smartflow's Slide Retainer with Limit Switch

- NEW! Smartflow's Versaswitch

- Global Thinswitch

- Z-Series Locks with life-time guarantee

- Front Loading Tapered Interlocks

- MoS2 Coated Nitrided Ejector Pins

- SRTM Slide Retainers

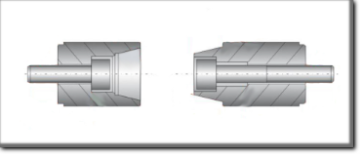

Front Loading Tapered Interlocks

Tapered Interlocks provide positive metal-

Whilst we stock various types of Round Tapered Interlocks, the Euro design offers destinct advantages in that it is "front-

This results offers an extreme advantage! Should alignment problems occur during production, the units can be accessesed and replaced from the split line whilst the mould is still in the machine. In other designs the mould would need to be removed from the machine and stripped in order to access the cap screws from behind the plate in which the tapered interlock is secured.

Download the Specification sheet here to see sizes available.

See other Round Tapered Interlocks here. (Including "DME")